Week 3

This week I have a finished part in hand. I mean, it’s not a part with any real functionality, but I achieved my goals: learn how to square and dimension stock.

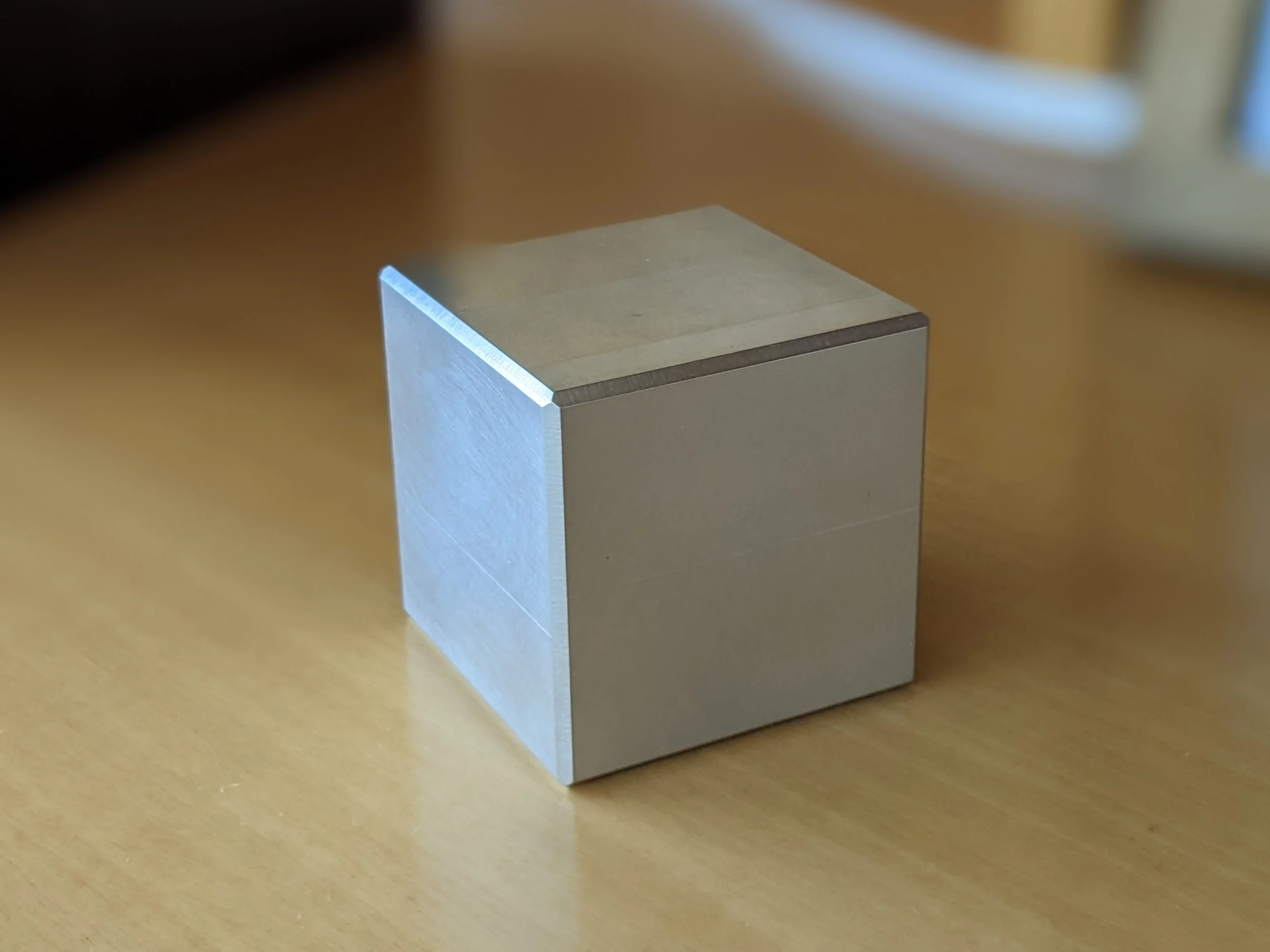

I started with a rough chunk of aluminum from the mill and finished with a cube that is 2.000” on each side, ±.0003”, along with a 1/16” chamfer (photo 1). I’d be happier if the accuracy was more like ±.0001” but it’s not bad for my first time. Unfortunately I don’t have the instruments needed to measure squareness. The best I can do for now is to check squareness using an engineer’s square.

While learning how to square and dimension stock, I picked up a few more skills: tramming a vise using my dial test indicator (photo 2), setting the zero point using an edge finder and 1-2-3 block, and finding the right feed/speed for facing with my shell mill (photo 3).

Next steps:

learn how to square and dimension on the CNC mill

design and machine a part on the CNC mill

———

P.S. The argon tank at the shop is still empty and probably won’t get refilled for at least a few more weeks ☹️

Photo 1

Photo 2

Photo 3